Reverse Engineered Easel: PROGRESS I

Out of the options I considered in my last blogpost, I decided to reverse engineer the easel via 3D modelling in Rhino 7. In preparation for the 3D modelling, I decided to count, label, and sketch all the metal/plastic components and wheels. I will begin designing those forms because they are most challenging parts for this project.

1) Disassembling & sketching all the metal/plastic components

I roughly sketched each metal/plastic component and kept track of its location by placing their labels on the image to the left. I gave each type of component a letter from A-K and colour coded them for clarity.

I also kept track of how many times each figure is repeated in the model.

I noticed that each piece of wood already has a little label with a number on it, so I will count them all and organize them on a similar chart.

2) Selecting the first component to model

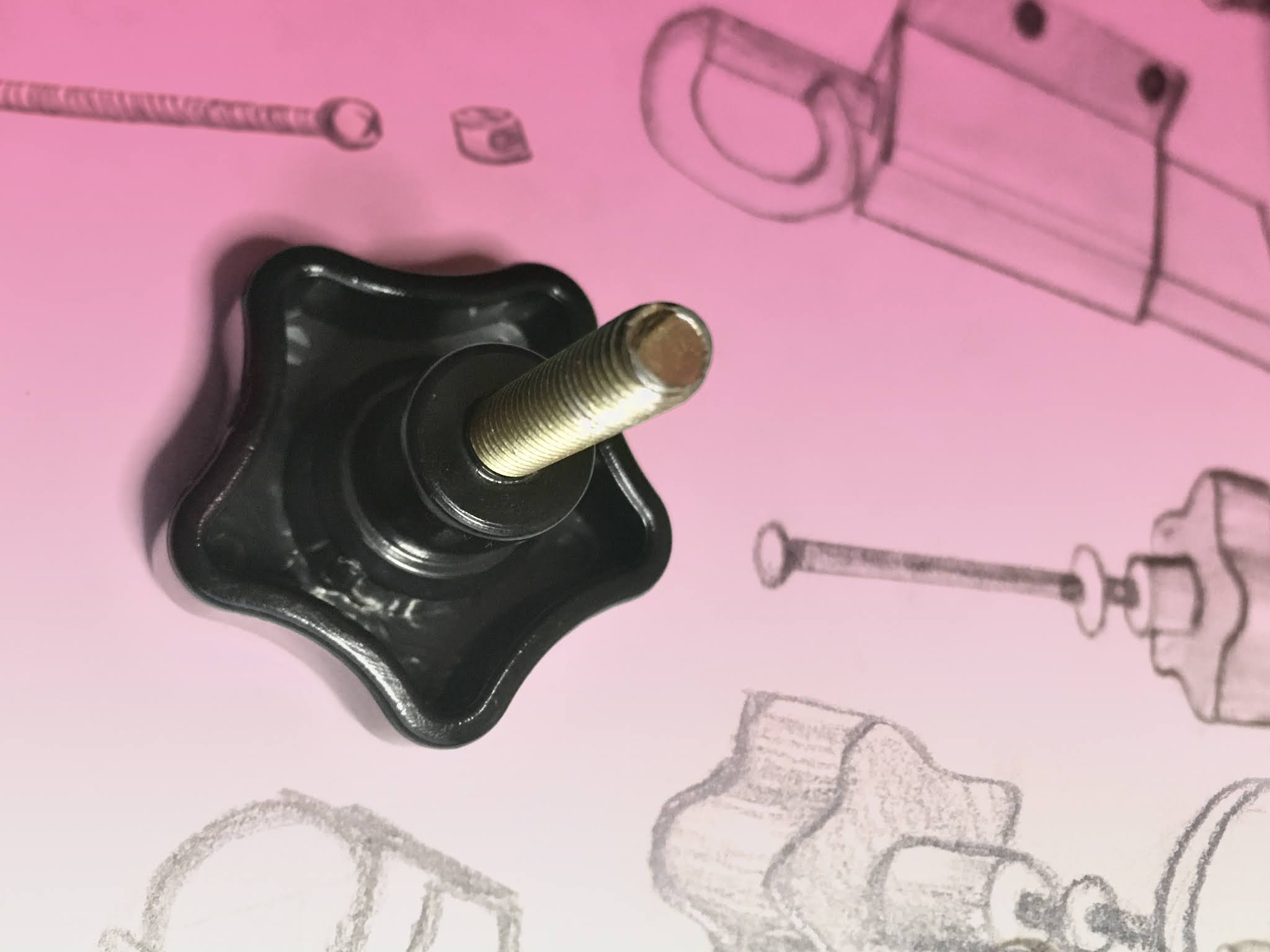

I am starting off with modelling "J," which is the screw and metal piece. The screw is used to loosen the top holder of the easel and change its position. The position of this piece is regulated depending on the height of the canvas or paper being held.

3) Measuring and modelling components

For many years, I've had a very decent Skill Tech dial caliper. At the start of this project, I predicted that it wasn't the ideal tool because it takes me a long time to make sure that each measurement is correct. So, a few weeks ago, I investigated different types of digital calipers online. I decided to buy the iGaging caliper which had good reviews and would make the measuring process easier. However, there was a problem with the order and it has not arrived yet. So, I am trying to make the dial caliper work for now.

I modelled and rendered the little metal piece, which is what the big screw presses up against to keep the whole wooden section in place. I'm sure this component has a name but I can't figure it out. The two thin pieces that extend from the sides have a slight edge fillet. This is because the original piece was a continuous piece of metal (including the two arms) and it was likely bent into its shape.

|

| Top view photo of the screw head |

Since the plastic screw head has a curve, I am not sure how to extrude my 2D outline. I guess that I might have to use the network surface command?

|

| Uncapped spiral extrusion |

Comments

Post a Comment